For Maryland builders, attic insulation is not a last-minute detail or a task to squeeze in at the end of the build. It is a code-driven system that directly affects energy compliance, inspection outcomes, long-term home performance, and liability exposure.

Maryland energy codes and U.S. Department of Energy guidance require R-49 or higher attic insulation levels for new construction homes. Reaching that target typically means installing roughly 15 inches of fiberglass insulation or about 13 inches of dense-pack cellulose, depending on material choice. Hitting those numbers consistently, without compromising safety, ventilation, or air sealing, requires coordination across trades and a solid understanding of building science.

That is why experienced builders rely on professional insulation contractors when looking for Baltimore attic insulation or Washington D.C. metro attic insulation as part of the core construction team, rather than attempting to self-install it.

Attic Assessment and Preparation

Before any insulation is installed in a new construction attic, professional contractors assess and prepare the space as part of the proper build sequence. Skipping or rushing this step is one of the most common reasons insulation jobs fail inspections or underperform in the long term.

Safety First

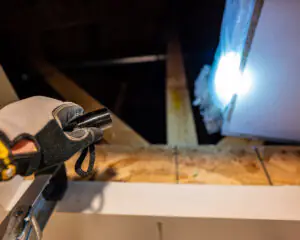

Professional insulation contractors bring trained crews equipped with proper personal protective equipment and established safety protocols. This reduces builder liability and protects workers from falls, electrical hazards, and exposure to materials.

Experienced crews also establish safe walkways and attic access routes to prevent damage to ceiling drywall, truss chords, and air barriers. Partnering with an insured insulation contractor transfers a significant portion of jobsite risk away from the builder.

Inspecting Wiring and Fixtures

Before insulation is installed, contractors coordinate with electrical trades to verify that all wiring and fixtures are complete and code-compliant. This includes identifying exposed wiring, open junction boxes, or improperly installed fixtures that cannot be safely buried. Catching these conflicts early avoids failed inspections, costly rework, and schedule delays that often fall back on the builder.

Evaluating Attic Systems and Ventilation Setup

Professional installers inventory attic systems before work begins. That includes locating HVAC equipment, ductwork, chimneys, exhaust fans, and flues, and planning insulation placement around them.

Code requires clearances around heat-producing equipment. Insulation must typically be kept at least 3 inches away from non-IC-rated recessed lights and 2–3 inches from chimneys or flues, often using metal flashing or fire-resistant barriers. Contractors also verify that bathroom fans and dryer vents exhaust outdoors rather than venting warm, moist air into the attic, which is prohibited due to the risk of condensation and mold growth.

Sealing Attic Air Leaks: The Critical First Step

Insulation slows heat transfer, but it does not stop air movement. In Maryland, both insulation levels and air tightness matter for energy code compliance and to prevent heat loss through the attic.

Professional contractors treat attic insulation as part of a whole-house air sealing strategy. Before insulation is installed, crews seal top plates, mechanical penetrations, and framing gaps throughout the attic plane.

Common sealing locations include plumbing vents, wiring penetrations, recessed lights, exhaust fans, wall tops, ducts, flues, and attic access hatches.

Small gaps <¼” are sealed with caulk or acrylic sealant. Larger penetrations are sealed using expanding spray foam. Large openings are covered with rigid foam or drywall and sealed at the edges. Attic hatches and doors are weather-stripped and insulated around the hatch itself to prevent leakage.

Maryland Energy Code Requirements Builders Must Meet

New homes in Maryland must meet a defined level of air tightness, typically verified through blower-door testing at the end of construction. Homes must fall below a specified air-leakage rate, usually around 3–5 air changes per hour at 50 Pascals, depending on jurisdiction and code cycle.

Builders who self-install insulation often underestimate the extent to which attic air leakage contributes to failed blower-door tests. Professional insulation contractors understand how insulation, air sealing, and ventilation work together to meet code the first time.

Ensuring Proper Attic Ventilation

Attic ventilation plays a crucial year-round role in home performance.

In winter, ventilation helps keep the roof deck cold, reducing the risk of ice dams. In summer, it allows hot air and moisture to escape, lowering attic temperatures and reducing stress on HVAC systems.

Attic Ventilation Requirements

The standard guideline is the 1:150 rule, which means one square foot of net free vent area per 150 square feet of attic floor space. Under certain IRC conditions, this can be reduced to 1:300 when intake and exhaust vents are balanced and other criteria are met.

For example, a 900-square-foot attic requires approximately 6 square feet of vent area using the 1:150 rule.

Balanced Intake and Exhaust

Professional installers split the ventilation between soffit intake vents and high-exhaust vents near the ridge. A roughly 50/50 balance supports natural convection and consistent airflow.

Attic Baffles (Rafter Vents)

Baffles are installed at the eaves to maintain a clear airflow channel above insulation. They prevent insulation from blocking soffit vents, a common attic installation error.

Contractors install baffles in each rafter bay and may add blocking to contain loose-fill insulation and keep ventilation paths clear.

Choosing the Right Insulation Material

Professional insulation contractors help builders select materials based on framing complexity, performance goals, and budget.

Fiberglass Batts and Rolls

Fiberglass batts and rolls are pre-cut to fit between joists and rafters and are best suited for open spaces with standard spacing and minimal obstructions.

They typically provide R-3 to R-3.5 per inch. Batts are affordable and widely available, but performance depends heavily on precise installation. Batts must fit snugly without compression, gaps, or overlaps.

Contractors often install a second perpendicular layer to reduce thermal bridging and achieve an R-49 or higher rating.

Loose-Fill (Blown-In) Insulation

Loose-fill insulation, either cellulose or blown fiberglass, conforms well to irregular spaces and provides seamless coverage.

Cellulose typically delivers R-3.5 to R-3.7 per inch, while blown fiberglass ranges from R-2.2 to R-2.8 per inch. Cellulose reaches R-49 at approximately 13 inches, compared to greater depths required for low-density fiberglass.

Although cellulose can settle by up to 20% over time, professional installation at the proper density minimizes this risk. Contractors use depth markers and commercial-grade blowing equipment to ensure even coverage and correct compaction.

Spray Foam Insulation

Spray foam is a premium insulation option that provides both insulation and air sealing in a single application. It is sprayed as a liquid that expands to adhere to surfaces.

Closed-cell spray foam offers R-6 to R-7 per inch, while open-cell provides around R-3.5 per inch. Spray foam is commonly applied to the underside of the roof deck to create a conditioned, unvented attic. It is well-suited for attics with HVAC equipment or planned living space.

This approach requires certified installers, specialized equipment, and a temporary vacancy during application. It is the highest-cost option but delivers exceptional air-sealing and thermal performance when installed correctly.

Rigid Foam Board (Targeted Use)

Rigid foam board is typically used for specific attic applications such as insulating attic access hatches or kneewalls. It provides approximately R-4 to R-6 per inch, depending on the type. While it can serve as a vapor barrier when foil-faced, it is not typically used to cover an entire attic floor; however, contractors may use it in combination with other types for targeted solutions.

Installation Best Practices: Why Expert Installation Counts

Achieving the Right Insulation Depth

Maryland guidelines recommend a minimum of R-49, with many builders opting for R-60 for added performance. Professionals calculate the required depth and install insulation evenly, including critical edge areas near soffits.

Complete, Even Coverage

Thin spots and gaps create thermal bridges, reducing insulation performance. Contractors fit batts tightly, cut around obstructions, add secondary layers, and level loose-fill insulation using controlled blowing techniques and depth gauges.

Protecting Heat Sources

Professionals follow code requirements for clearances around lights, chimneys, and heat sources. Non-IC-rated recessed lights are protected with covers or require air gaps. Chimneys and stovepipes maintain required clearances using cut-back insulation or metal flashing. Electrical boxes are never buried without covers.

Preserving Ventilation Paths

Installers ensure that soffit vents and airflow paths remain unobstructed throughout installation. Final eave inspections confirm insulation has not shifted or blocked intake vents.

Vapor Barrier and Moisture Control

Maryland’s mixed-humid climate makes moisture management critical. Standard practice is to install a vapor retarder on the warm-in-winter side of the attic floor insulation. Contractors avoid double vapor barriers by leaving additional insulation unfaced and by correcting high-humidity sources, such as improperly vented bathroom fans.

Final Inspection and Cleanup

Professional jobs conclude with a final inspection to confirm coverage depth, baffle placement, and the completeness of air sealing. Attic access hatches are insulated and weather-stripped; pull-down stairs may receive insulated covers; and installers often leave insulation certificates documenting the final R-values. Work areas are left clean and free of debris.

Enjoy the Benefits of a Professionally Insulated Home

Homes insulated correctly from day one deliver measurable benefits. New homeowners experience warmer upper floors in winter, cooler rooms in summer, fewer drafts, and improved home comfort. HVAC systems operate under less strain, improving efficiency and longevity.

Proper attic insulation helps reduce energy loss, lower utility bills, minimizes the risk of condensation, and prevents ice dams. For builders, it also means fewer callbacks, smoother inspections, and stronger long-term performance of the homes they deliver.

Partner With DeVere Insulation

Maryland energy code requires a minimum of R-49 attic insulation for new construction. DeVere Insulation helps builders meet and exceed those requirements through professional installation, trade coordination, and building-science expertise.

Contact DeVere Insulation to discuss attic insulation solutions and builder partnership opportunities for your next Baltimore attic insulation project.

References:

Accurate Insulation. (n.d.). How much does cellulose insulation settle? https://www.accurateinsulation.com/blog/how-much-does-cellulose-insulation-settle/

Indiana Spray Foam. (n.d.). How to properly seal window gaps. https://www.indianasprayfoam.com/blog/how-to-properly-seal-window-gaps

Insulation Institute. (n.d.). Attics and ceilings. https://insulationinstitute.org/im-a-homeowner/installation/doing-it-yourself/attics-and-ceilings/

Maryland Energy Administration. (n.d.). Your home and the energy code [PDF]. https://energy.maryland.gov/documents/yourhomeandtheenergycode.pdf

The Spruce. (n.d.). Cellulose insulation basics. https://www.thespruce.com/cellulose-insulation-basics-1821904

University of Maryland Extension. (n.d.). Home energy insulation. https://extension.umd.edu/resource/home-energy-insulation

U.S. Environmental Protection Agency. (n.d.). About attic ventilation. ENERGY STAR. https://www.energystar.gov/saveathome/seal_insulate/do-it-yourself-guide/about-attic-ventilation

U.S. Environmental Protection Agency. (n.d.). Attic insulation project. ENERGY STAR. https://www.energystar.gov/saveathome/seal_insulate/attic-insulation-project